|

Go Back

Start

Page

Parts

Book

Photos & #

Page

Links

Head Torque

Valve Parts

Valve

Covers

& Gaskets

Valve Lift

&

Duration

40 HP

Valves

*Valve

Part Numbers

Q&A

Valve Noise

Purchase with

PayPal

12/09/02*

|

--- >> PROCEDURE << ---

Now for adjusting those Beetle valves. Always adjust valves when the

engine is cold, not warm but "Dead Cold".

Rotate the crankshaft Clock-wise (this can be done

with the Generator Pulley Nut (9) if the belt is held tight.)

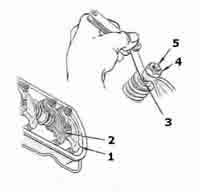

With the distributor cap removed, line up the rotor (5) with the #1 cylinder spark plug wire.

(At the small

notch (6) on the top edge of the distributor body)

The TDC (0') mark on the crank pulley (8) should line

up with the crankcase center parting line.(7)

Both intake (2) and exhaust valves (1) are set at .006

unless your cam card says different or you have a

40hp. Setting 40HP Valves->*Click

The following method has worked best for us.

1). Jack up the right side of the car (easier to get to

the valves, and keeps the oil from running out when

valve cover is removed).

2). If not on TDC #1 as described above turn crankshaft clock-wise until the #1 cylinder intake valve

(1) closes

(Intake valve is second one from the front on right side).

Continue turning the pulley clock-wise until the TDC mark (8) on the pulley lines up with the crank case

parting line (7) (Top Dead Center on the compression stroke.)

If its a stock beetle and the distributor drive was installed properly the ignition rotor

(5) will be pointing behind

the right rear wheel, and in line with the notch (6) on the distributor body.

If you don't have a degree pulley then take special care to mark TDC and BDC on your crank pulley or get one

that's already marked.

3). Ok now we are on TDC on compression on #1 cylinder. Set both valves on #1 cylinder to

.006". (or what your

aftermarket cam card suggested.)

When you feel a slight drag on the .006" feeler gage (3), tighten the 13mm nut

(4) Then recheck the clearance

to make sure nothing moved.

4). Next turn the crank counter clock-wise, that's backwards ½ turn (180'), so the BDC mark lines up with the case parting line (7) and set both intake and exhaust valves on #2 cylinder to .006"

Now the right side is done.

We always check the valve covers on the head without the gasket to make sure they are flat and don't rock

from side to side. (Bent valve covers will leak.)

Remove all oil from the sealing surface and replace the valve cover using a new gasket.

The head surface should be bare, no oil or sealer.

Gasket sealer can be applied to the valve cover, But "Do

Not Use" Silicon Seal.

5). Next jack up the left side of the car and remove the valve cover.

Rotate the crank ½ turn counter clock-wise until the TDC mark aligns with case parting line, and set both of

#3 valves to .006".

6). Then rotate the crank ½ turn counter clock-wise again to the mark and set both #4 valves to

.006".

Wipe all oil off the sealing surface and replace the valve cover using a new gasket.

If any of the valves were tight (less then .006" clearance) be sure to make a note of it in your log

book for later

reference.

Note: If the valve stem is worn then the feeler gauge

simply bridges the dish. The feeler gauge can not flex enough to

accurately check the gap, so you end up with loose valves and

possible a ticking noise. Try adjusting it with an

indicator, install lash caps or install the captive ball

adjusters. (remember to install the spacers under the rocker

stands when using captive balls or lash caps so the rocker geometry

will be correct ) The rocker needs to move a little more

then the thickness of a dollar bill (.004"). It's far

better to have the valves a little loose then to tight, as tight

valves cause all kinds of problems.

--- >> Important << ---

If you do not know the history of your air cooled VW motor it is very important to set the valves as soon

as

possible.

The VW air cooled engine will always let you know when it's getting ready to drop an Exhaust Valve.

But you must have a little information to understand the warning signs.

The exhaust valve will start stretching before it lets go.

That's why we set the valves as soon as we get the engine, and note the mileage and valve clearance in our

log book.

Set the valves, and then after approximately 1500 miles we check the valves again, and enter the figures in

our

log book.

If valve clearance has closed up, we check them a third time in another 1500 miles.

Then If the clearance has closed up again, we stop driving and start rebuilding the heads.

If the valve clearance stayed the same we're in good shape and can start checking the valves every 6000 miles

or every other oil change.

Any time an exhaust valve tightens up we recheck in 1500 miles to confirm the valve is actually stretching.

About 90% of the time the first valve to let go will be the #3 cylinder exhaust valve.

So keep an eye on valve clearance and happy motoring.

--- >> More on VW Valves << ---

Before Stainless Steel Exhaust Valves where used, about 95% of Beetle engine failures were caused by

"Dropped Valves".

A Dropped valves is when the exhaust valve gets too hot, and the valve stem stretches until it breaks.

The valve head falls into the cylinder, and it destroys the piston, the head, and sometimes the rod and more.

Valves break for only one reason, they are "TOO HOT".

Exhaust valves pick up heat from the combustion chamber and from the hot exhaust gas flowing past them.

They get rid of this heat primarily by transferring it to the valve seat when they are closed, plus a small amount

of heat is transferred through the valve guide.

If the valves don't seat properly and/or the guide is loose, they get Very Hot, and they stretch until they break.

The number-three-cylinder exhaust valve usually goes first.

We recommend adjusting your valves every 6000 miles or with every other oil change.

By keeping an eye on valve clearance you can tell when the valves start to stretch.

Keeping a log book can save you big bucks.

If the valve clearance ever tightens up .003" or more, make a note of it, and then recheck the clearance after

another 1500 miles.,

If the valve clearance closes up the second time, it's time to stop driving your bug and replace or rebuild the

heads.

This time be sure to use good stainless steel exhaust valves.

We have Beetle engines still running 250,000 miles after Stainless Steel exhaust valves were installed.

With stock valves your lucky to get 95,000 miles before a valve lets go.

Question w/Answer On Rocker Arm Nose (clicking)->*Click

Many race motors use Chromoly pushrods which expand less then

the stock Aluminum. For this reason the valves are set at .002

but remember most race motors have the valves checked after

every race.

When setting the valve clearance on aftermarket cams always

follow the cam grinders recommendation.

Go Back

Victor Comp. Products Inc. **--Vic's--**

Phone 816-650-3535 • 230 S Hudson St., Buckner, Missouri, 64016, US

|